What Is The Cost Of Repairing A Failed Backflow (Double Check)?

Nothing is more frustrating than having your backflow assembly fail its annual inspection. You start wondering, how in the heck did this happen and how could I have prevented it? Most the time, it is something that you cannot prevent because it is typically something that is out of your control. Luckily, most failed backflow assemblies are repairable so they don't need to be completely replaced.

What counts as a failed test?

First things, first...

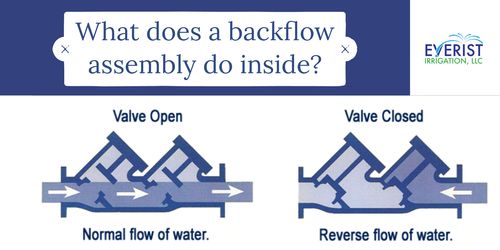

The purpose of a backflow test is to ensure that water does not flow from your irrigation side of the double check to the drinking water side of the double check.

In order for the assembly to pass it must maintain at least 1.0 PSID (pounds per square inch differential). This means that that there is at least 1.0 psi difference between checks which then tells us that the check closed. If the PSID equals zero, this represents both chambers have equal pressure. This tells us that the assembly leaked and water can flow back into your drinking water.

We have certified testers on our crew that are certified through the Oregon Health Authority and we have special testing gauges that are calibrated annually to ensure that the test are completed accurately.

The purpose of a backflow test is to ensure that water does not flow from your irrigation side of the double check to the drinking water side of the double check.

In order for the assembly to pass it must maintain at least 1.0 PSID (pounds per square inch differential). This means that that there is at least 1.0 psi difference between checks which then tells us that the check closed. If the PSID equals zero, this represents both chambers have equal pressure. This tells us that the assembly leaked and water can flow back into your drinking water.

We have certified testers on our crew that are certified through the Oregon Health Authority and we have special testing gauges that are calibrated annually to ensure that the test are completed accurately.

Backflow Failure #1: Installation or Repair Debris

approx $30 - $120

The most common time we see assemblies fail is after a repair to the mainline has been done. In the event that you had some work done, or had a broken pipe, sometimes pipe shavings and/or pieces of pipe can get caught between the checks or poppits, that can cause the checks not to seal.

Sometimes the water company will do work on the water system and bits of pipe can also enter the system and make its way into your irrigation double check.

Sometimes the water company will do work on the water system and bits of pipe can also enter the system and make its way into your irrigation double check.

Backflow Failure #2: Worn Springs

approx $35 - $55

Sometimes the springs will get worn out due to age. To repair this problem, we would need to shut off the water to the assembly, remove the checks and replace the springs.

Backflow Failure #3: Broken Checks

approx $40 - $65

There has been times when I have opened up a check valve where the checks are completely destroyed. Still to this day, I have no clue why this is happening, but I just assume it is wear and tear on the components.

Backflow Failure #4: Shut-off valve leaks

approx $40 - $200

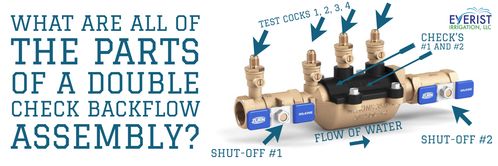

One backflow assemblies their are two shut-offs that are required for testing. Both of these valves need to completely close in order to do a test on your device. If during the test we find that water continues to flow through the these shut-offs, the test cannot be completed and it would result in a failed test.

Many contractors will tell you this assembly might need to be replaced, but likely just the shut-off valve would need to be replaced. Shut-off #2 can be a typical ball valve, but shut-off #1 is a "tapped" ball valve (allows for a test cock to be screw into it) and needs to be replaced with a "tapped" ball valve. The price of a tapped ball valve costs more because of the manufacturing of this uncommon ball valve.

Replacing a shut-off valve can be a simple task or a difficult task depending on your current installation of your backflow assembly. Some devices need to be cut out while others have unions on each end that allows for the assembly to be removed for easy service. All assemblies are required to have unions upon installation, but some were omitted by the installer to cut corners in an effort to enhance profits.

Many contractors will tell you this assembly might need to be replaced, but likely just the shut-off valve would need to be replaced. Shut-off #2 can be a typical ball valve, but shut-off #1 is a "tapped" ball valve (allows for a test cock to be screw into it) and needs to be replaced with a "tapped" ball valve. The price of a tapped ball valve costs more because of the manufacturing of this uncommon ball valve.

Replacing a shut-off valve can be a simple task or a difficult task depending on your current installation of your backflow assembly. Some devices need to be cut out while others have unions on each end that allows for the assembly to be removed for easy service. All assemblies are required to have unions upon installation, but some were omitted by the installer to cut corners in an effort to enhance profits.

Replace the Backflow Assembly

approx. $200 - $550

This is an extreme case if a backflow assembly needs to be replaced. Often time this is due to freezing the body, then replacing the double check is the best way to go about alleviating water squirting everywhere.

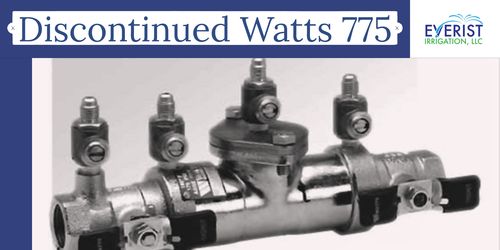

Tops, test cocks, internal parts and ball valves are pretty much readily available if needed for repair. In some circumstances they are not. Some assemblies are discontinued but parts are still available for them. The Watts 775 Double Check, however, is discontinued and parts are also NOT available for them. A failed backflow test would result in needing to replace the assembly. This assembly is in the Central Oregon area. Many assemblies were installed from 1998 until around 2003. With the building boom and the affordable price of this assembly, it is widespread through Bend, Redmond and Sisters.

Tops, test cocks, internal parts and ball valves are pretty much readily available if needed for repair. In some circumstances they are not. Some assemblies are discontinued but parts are still available for them. The Watts 775 Double Check, however, is discontinued and parts are also NOT available for them. A failed backflow test would result in needing to replace the assembly. This assembly is in the Central Oregon area. Many assemblies were installed from 1998 until around 2003. With the building boom and the affordable price of this assembly, it is widespread through Bend, Redmond and Sisters.

Repairing an assembly to be compliant with your water company can be fairly easy to do. Contact Everist Irrigation if you suspect your backflow assembly may need replacement; you can find us on the web or call us at (541) 362-1389.

Posted in Backflow, Services, Spring

Posted in backflow assembly, failed backflow, bend, central oregon, irrigation, irrigation repairs, redmond, sisters, double check, failed backflow repair, backflow assembly repair

Posted in backflow assembly, failed backflow, bend, central oregon, irrigation, irrigation repairs, redmond, sisters, double check, failed backflow repair, backflow assembly repair

Looking for something? Search here!

Categories

Recent

Understanding the Various Water Sources for Residential Irrigation Systems

February 13th, 2023

The Role of Soil Type, Climate, and Irrigation Scheduling in Residential Irrigation Design and Planning

February 13th, 2023

FAQ's about Winterizations:

October 7th, 2022

The Ony 2 Reasons You Should Ever Consider Installing a Sprinkler System

February 9th, 2021

What is a Man-Hour? [Explained]

January 24th, 2020

Archive

2023

2022

October

2020

January

2019